INTRODUCTION

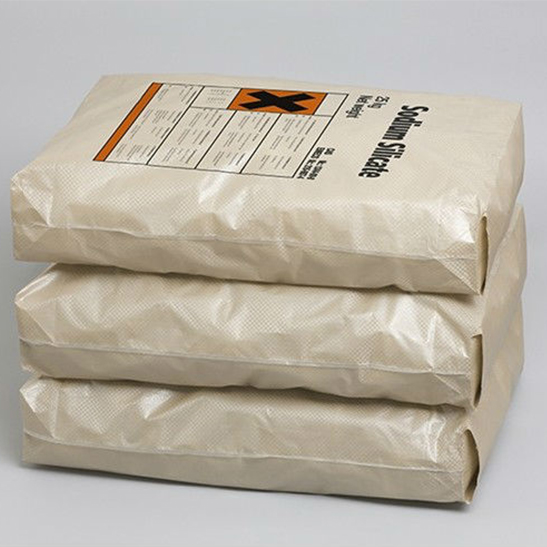

When you are in an industry that requires specific packaging solutions for your products, choosing the correct bags is as important as producing quality products. One of the most prominent packaging solutions in the industry, Block Bottom Bags, truly stands out for its qualities. Also known as AD*STAR bags, Block Bottom Bags are ideal substitutes for your costly paper bags. Shaped as a brick-like form, it is widely used in the various industries. Adding our special ALITA touch, you can expect only the highest quality products.

FEATURES

- UV Protection from 200 to 1600 Hours

- Valve for easy filling

- Cannot be tampered as is hermetically (air-tight) sealed

- Moisture resistance

- Tear-proof

- High load-bearing capacity

MATERIAL COMBINATION

Majorly PP woven Block Bottom Bags are made using coated & printed woven fabric. On the other hand BOPP laminated Block Bottom bags are made using BOPP laminated & printed woven fabric.

1. PP WOVEN BLOCK BOTTOM BAGS

- Shape of bottomBrick shape

- MaterialCoated PP woven fabric

- Tap Width2.5 mm – 5 mm

- Fabric50 GSM – 80 GSM

- Coating17 GSM – 25 GSM

- Width300 mm – 600 mm

- Length430 mm – 910 mm

- Bottom Width80 mm – 180 mm

- ColorAs per requirement

- TypeValve or Open mouth

- Valve MaterialCoated PP Woven Fabric

- Attachment of PatchesSealing process with hot air & pressure

- Air PermeabilityAs per customer requirement

2. BOPP LAMINATED PP WOVEN BLOCK BOTTOM BAGS

- Shape of bottomBrick shape

- MaterialBOPP Laminated PP woven fabric

- Tap Width2.5 mm – 5 mm

- Fabric50 GSM – 80 GSM

- Coating17 GSM – 25 GSM

- BOPP Micron15 - 30 Micron

- Width300 mm – 600 mm

- Length430 mm – 910 mm

- Bottom Width80 mm – 180 mm

- ColorAs per requirement

- TypeValve or Open mouth

- Valve MaterialBOPP Laminated PP Woven Fabric

- Attachment of PatchesSealing process with hot air & pressure

- Air PermeabilityAs per customer requirement

- SpecialityOffer Backseam construction With big print in Gusset same like top & bottom

ALITA'S SPECIALITY

Quality over everything is our motto here at ALITA. We understand the customer requirements to its core and provide an optimum solution for it. Block Bottom Bags are essential for various significant industries and we treat it, such as. Our specially designed production methods result in high-quality bags with all the customization.

PRODUCTION CAPACITY

We are equipped with all the ultra-modern machinery and equipment. Block Bottom Bags are one of our specialty products, and we never compromise in its qualities. We can produce as high as 150,000 Block Bottom Bags per day.

CHOOSE US

We are living in a time where trends are changing every day. It is essential to acknowledge the fact and stay up to date with it. We are known for our premium quality products, and we promise to deliver that in our Block Bottom Bags as well. Having all the unique qualities, it is safe to say that our Block Bottom Bags will prove to be your ultimate packaging solution.

MANUFACTURING PROCESS

The manufacturing of Block Bottom Bags involves various vital steps. It begins with loading a tubular roll of coated/laminated – printed woven fabric on the machine. As it passes through the machine, the fabric is first cut according to the bag cut length. Then, at the end(s) of the bag, one side of the fabric is flipped over the other and sealed hermetically (air-tight) using heat and pressure. Another roll unwinds itself to provide a rectangular strip to overlap the bag’s tight end(s). This process is called patching. The patch’s material is the same as that of the bag, and the size is predetermined. The creation of the valve takes place while the patch is attached. Finally, the block bottom bag is collected at the end of the machine.